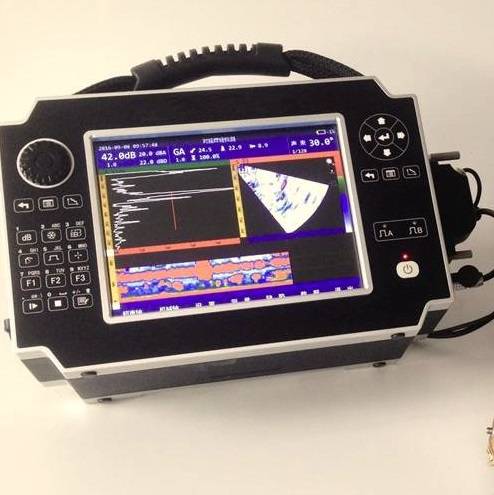

TMPA600 Portable Phased Array Ultrasonic Flaw Detector

★64 Channel Configuration

★State-of-the-art water- & oil -proof TG Touch Pad

★Anti-hit, omnisealed and fan free metal housing of low power consumption

★Full course recording, smart management of Double-Li-Battery with long life

★”Solution” trademark, independently self-made instruments and transducers, processes provider

“Dynamic Depth Focusing”On “Dynamic Depth Focusing”Off

Features:

16:64 configuration, maximum active aperture of 16 elements and maximum 64 elements available. T-R mode (twin PA probes) optional

Delay precision up to 1ns; evident inhibition on sidelobes as to promote vertical and horizontal discernibility, as well as to improve imaging definition.

Real-time A\L\S\C scan responsive imaging. Encoding or time-basing optional for continuous data recording, acquiring 100% original data.

Curve compensations like ACG and TCG are available prescribed by ASME, to tackle the problems caused by the uneven energy distribution during S-scan as well as measurement errors. The consistency of echo sensitivity is higher under ACG and TCG.

Omnisealed, water- & dust-proof but capable of fan-free heat-dissipation, upstanding against various adverse conditions.

· Focal laws can be generated automatically soon according to angle, focal length, scan mode, parameters of probe and wedge, with auto-optimized stepping of S-scan.

Real-time dynamic focusing creates full uniformity, as the profound contributor to quality image.

55dB analog gain range and 35dB digital gain range; 3 options of filtering: 0.5-9.7MHZ, 4.0-12.5MHZ, and 6.7-20.8MHZ. Auto-optimization of pulse width according to probe frequency, excellent noise processing. Image smoothing, enhancement of image quality.

11-inch, TG and full WVGA resolution (800×600) TFT display, best feed outdoors or under strong light.

State-of-the-art water & oil -proof TG capacitive screen, for touching control, sensational experience!

Massive storage for A\L\S\C scan images, and reports concomitant

USB port for quick data transferring; HDMI port for grafting display with unlimited size

AC\DC optional, allowing 2 batteries engaged as co-powersuppliers and engagement takes shifts automatically according to power allowance, guaranting 6+ hrs of nonstop working.

| Functionality | PA Mode | PE Mode |

| PRF | 50Hz-10KHz | 25Hz-10KHz |

| Voltage | Bipolar ±45V -±100V, step: 5V | 25V -350V, step: 25V |

| Pulse Width | 20ns – 800ns, step: 5ns | 30ns – 1000ns, step: 5ns |

| Damping | 50 Ohm | 80\400 Ohm |

| Sampling Rate | 100MHz | 200MHz |

| Delay Precision | 1ns | N/A |

| Reception Delay Available | 0.0 ~ 90dB | 0.0 ~ 110.0dB |

| Filter | Auto | Digital Filtering |

| Rectification | PW, NW, FW, RF, Smooth-up | PW, NW,FW,RF |

| Rejection | 0 -80% | 0 – 80% |

| Scan Modes | L\S\C | A |

| TriggeringScan linesAngle | Time-based\Encoder128L\S-scan: -85°-+85° | N/AN/AN/A |

| Functionality | PA Mode | PE Mode |

| Calibration Modes | Velocity\TCG\ACG | Velocity\Probe Delay |

| Display Reachable | 0.0 ~ 1000mm, Min. 1mm | 0.0~2000mm(Steel LW); Min Step:0.1mm |

| Display Delay Availability | 1000mm | 2000mm |

| Display Shift Range | N/A | 2000mm |

| Unit | mm | mm |

| Gate | A; B | A; B |

| Gate Start | Full reachable range | Full reachable range |

| Gate Height | 5~95% | 5~95% |

| Alarm Modes | Sound & Light | Sound & Light |

| Spotting Modes | Peak\Flank | Peak\Flank |

| Readout | Amplitude; beam path; data of processed image | Amplitude; beam path |

| Discernibility | 0.5mm | 0.1mm |

| DAC\TCG | Max 20 joints; dynamic range 40dB | Custom, max 3 threads |

| ACG | Available | N/A |

| AVG | N/A | Standard |

Applications

● Conventional Inspection on Welded-seams (WS)

●Inspection on Al Alloy FSW seams

● Inspection on Welded-seams of Rail

●Inspection on Axles and Wheelsets of Railway Vehicle

● Inspection on Bolts

●Inspection with Restricted Movement like on Blade Roots

●Inspection on Butts of Tthylene Tube

●C-scan on Composites

●Field measurement