High definition Metallogrpahic Specimen Grinding And Polishing Machine - Metallographic Specimen Cutting Machine Model SQ 60 SQ80 SQ100 – TMTeck

High definition Metallogrpahic Specimen Grinding And Polishing Machine - Metallographic Specimen Cutting Machine Model SQ 60 SQ80 SQ100 – TMTeck Detail:

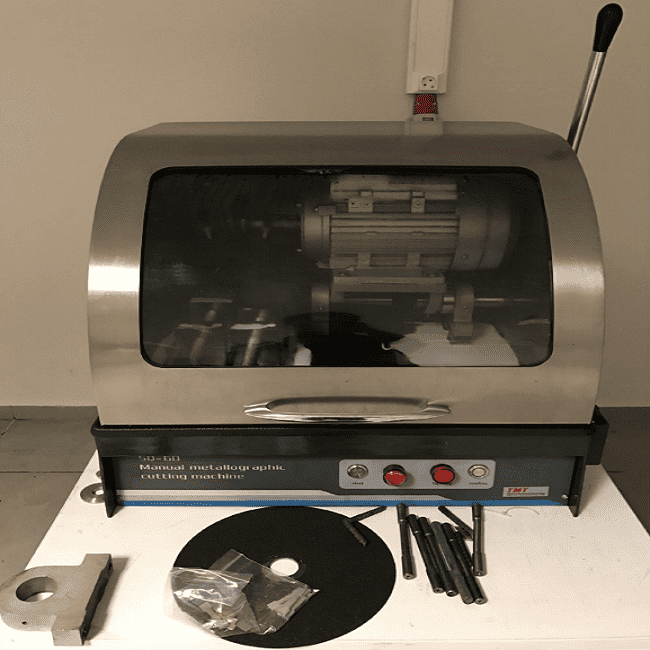

Metallographic Specimen Cutting Machine Model SQ 60 SQ80 SQ100

Model TMSQ-60 Metallographic Specimen Cutting Machine can be used to cut the general metallographic or petrographic specimen materials. To enable the machine to cut the best specimen in a safe state, this kind of machine is equipped with fully enclosed structure and fast clamping mechanism, and there is also a cooling tank for coolant recycling, in order to clear up the heat produced during cutting and avoid the metallographic or petrographic structure deforming of specimen because of heating influence. This machine features easy operation and reliable safety. It is the best instrument for specimen preparing and cutting.

Technical specifications:

1. Max. cutting section: Φ60mm

2. Rotate Speed: 2800rpm

3. Abrasive wheel: 250×2×32mm

4. Electric motor: 2.2KW 380V, 50Hz

5. Dimensions : 730×700×540mm

Model SQ-80 Metallographic Specimen Cutting Machine can be used to cut various metal and non-metal materials so as to get specimen and observe the metallographic or petrographic structure. The equipped cooling system can clear up the heat produced during cutting so that it will avoid the metallographic or petrographic structure deforming of specimen because of heating influence. This machine features easy operation and reliable safety. It is the necessary specimen preparing instrument for using in factories, scientific research institutes and laboratories of colleges.

Technical specifications:

1. Power: Three-phase four-wire (380V 50Hz)

2. Rotate Speed: 2800rpm

3. Abrasive wheel: 250×1.2×32mm

4. Max. cutting diameter: 80mm

5. Electric motor: Y2-100l-2 3.0KW

Model SQ-100 Metallographic Specimen Cutting Machine can be used to cut various metal and non-metal materials so as to get specimen and observe the metallographic or petrographic structure. The equipped cooling system can clear up the heat produced during cutting so that it will avoid the metallographic or petrographic structure deforming of specimen because of heating influence. This machine features easy operation and reliable safety. It is the necessary specimen preparing instrument for using in factories, scientific research institutes and laboratories of colleges.

Technical specifications:

1. Power: Three-phase four-wire (380V 50Hz)

2. Rotate Speed: 2800rpm

3. Abrasive wheel: 250×1.2×32mm

4. Max. cutting diameter: 100mm

5. Electric motor: Y2-100l-2 3.0KW

Product detail pictures:

Related Product Guide:

owing to good service, a variety of high quality products, competitive prices and efficient delivery, we enjoy a good reputation among our customers. We are an energetic company with wide market for High definition Metallogrpahic Specimen Grinding And Polishing Machine - Metallographic Specimen Cutting Machine Model SQ 60 SQ80 SQ100 – TMTeck , The product will supply to all over the world, such as: South Africa, Barbados, Sao Paulo, Why we can do these? Because: A, We are honest and reliable. Our products have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It will be highly appreciated.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.