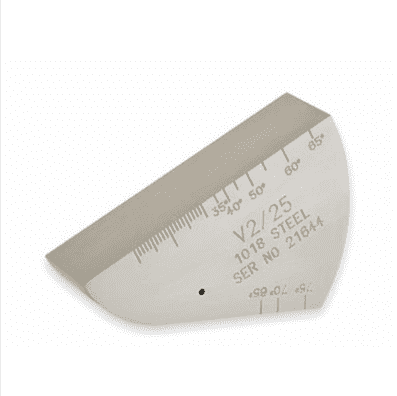

Good quality V2 Block Calibration - Penetrant Testing Specimen Precision Star Tam Panel Ndt – TMTeck

Good quality V2 Block Calibration - Penetrant Testing Specimen Precision Star Tam Panel Ndt – TMTeck Detail:

Penetrant testing test specimen

Model:TM-B3

All linear dimensions to the requirements of AS2083/2005, BS2704/1978/1983, where applicable. Heat treatment to the requirements of GB/T6394/2002. where practicable tolerances to (+/-0.1mm) unless otherwise stated. Treated to 920 degrees C for 30 minutes, water quenched, 650 degrees C for 3 hours, air cooled

Material standard:according to ISO 10474-3.1.B,JIS G 0415-3.1.B

Depth:100µm

Width target value:0.5µm

Test standard:ISO 3452-3:1998(E),JB/T6064

Model:TM-A5

All linear dimensions to the requirements of AS2083/2005, BS2704/1978/1983, where applicable. Heat treatment to the requirements of GB/T6394/2002. where practicable tolerances to (+/-0.1mm) unless otherwise stated. Treated to 920 degrees C for 30 minutes, water quenched, 650 degrees C for 3 hours, air cooled

Material standard:according to ISO 10474-3.1.B,JIS G 0415-3.1.B

Depth:100µm

Width target value:0.5µm

Test standard:ISO 3452-3:1998(E),JB/T6064

Model:TM-D

All linear dimensions to the requirements of AS2083/2005, BS2704/1978/1983, where applicable. Heat treatment to the requirements of GB/T6394/2002. where practicable tolerances to (+/-0.1mm) unless otherwise stated. Treated to 920 degrees C for 30 minutes, water quenched, 650 degrees C for 3 hours, air cooled

Material standard:according to ISO 10474-3.1.B,JIS G 0415-3.1.B

Depth:150µm

Width target value:0.5µm,1.0μ and 1.5μ

Test standard:ISO 3452-3:1998(E),JB/T6064

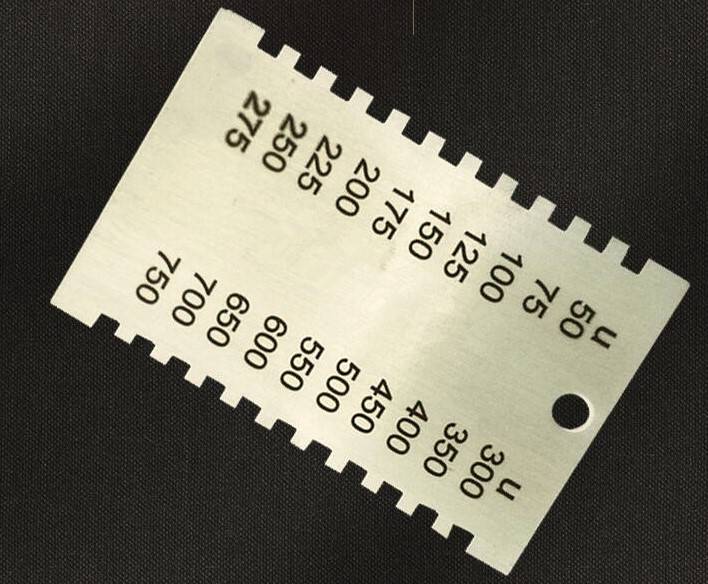

Model:TM-AB

Through the physical and chemical test type A block material for LY12 aluminum alloy for materials, the chemical components conform to the provisions of ASTM,GB/T3190

By means of a micrometer measurement block length is 76 + 0.1 ㎜, and the width fifty + / – 0.1 ㎜, thick and ± 1 ㎜. Cut along the length center evenly divided into two pieces, and in block A and B and unity Numbers, block length orientation and plate rolling direction. Milling, grinding the surface roughness after treatment for Ra = 1.2 u m – 2.5 u m.

Color: Visual its color is silvery white.

Oxidizing property :In -55 ℃ ~ 200 ℃ – store between three years not metamorphism, no oxidation,

Crack: In the same Numbers of the A and B block with dye penetrant inspection method measured random crack 3 μ m, 3 μ m ~ 5 μ m and more than 5 μ m open crack on one side not less than four, and there are two above width is not more than 3 μ m open crack. Block A and B on the surface crack distribution is similar.

ASTME165 standard

Product detail pictures:

Related Product Guide:

We'll make each hard work to become excellent and excellent, and speed up our measures for standing from the rank of intercontinental top-grade and high-tech enterprises for Good quality V2 Block Calibration - Penetrant Testing Specimen Precision Star Tam Panel Ndt – TMTeck , The product will supply to all over the world, such as: Bolivia, Rio de Janeiro, Juventus, Custom orders are acceptable with different quality grade and customer's especial design. We are looking forward to establish the good and successful cooperation in business with long terms from the customers of all over the world.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.