Chinese Professional Hardness Machine - The Impact Device of Hardness Tester – TMTeck

Chinese Professional Hardness Machine - The Impact Device of Hardness Tester – TMTeck Detail:

The Impact Device of Hardness Tester

Different Types of Impact Device

|

Material |

Hardness method |

Impact device |

|||||

|

D/DC |

D+15 |

C |

G |

E |

DL |

||

|

Steel and cast steel |

HRC |

17.9~68.5 |

19.3~67.9 |

20.0~69.5 |

22.4~70.7 |

20.6~68.2 |

|

|

HRB |

59.6~99.6 |

47.7~99.9 |

37.0~99.9 |

||||

|

HRA |

59.1~85.8 |

61.7~88.0 |

|||||

|

HB |

127~651 |

80~638 |

80~683 |

90~646 |

83~663 |

81~646 |

|

|

HV |

83~976 |

80~937 |

80~996 |

84~1042 |

80~950 |

||

|

HS |

32.2~99.5 |

33.3~99.3 |

31.8~102.1 |

35.8~102.6 |

30.6~96.8 |

||

|

Hammered steel |

HB |

143~650 |

|||||

|

Cold work tool steel |

HRC |

20.4~67.1 |

19.8~68.2 |

20.7~68.2 |

22.6~70.2 |

||

|

HV |

80~898 |

80~935 |

100~941 |

82~1009 |

|||

|

Stainless steel |

HRB |

46.5~101.7 |

|||||

|

HB |

85~655 |

||||||

|

HV |

85~802 |

||||||

|

Gray cast iron |

HRC |

||||||

|

HB |

93~334 |

92~326 |

|||||

|

HV |

|||||||

|

Nodular cast iron |

HRC |

||||||

|

HB |

131~387 |

127~364 |

|||||

|

HV |

|||||||

|

Cast aluminum alloys |

HB |

19~164 |

23~210 |

32~168 |

|||

|

HRB |

23.8~84.6 |

22.7~85.0 |

23.8~85.5 |

||||

|

Brass(copper-zinc alloys) |

HB |

40~173 |

|||||

|

HRB |

13.5~95.3 |

||||||

|

Bronze (copper-aluminum/copper-tin alloys) |

HB |

60~290 |

|||||

|

Wrought copper alloys |

HB |

45~315 |

|||||

|

Non conventional impact devices |

DC(D)/DL |

D+15 |

C |

G |

E |

|

|

Impacting energy Mass of impact body |

11Mj

5.5g/7.2g |

11mJ

7.8g |

2.7mJ

3.0g |

90mJ

20.0g |

11mJ

5.5g |

|

| Test tip Hardness Diameter of test tip

Material of test tip |

1600HV 3mm Tungsten carbide |

1600HV 3mm Tungsten carbide |

1600HV 3mm Tungsten carbide |

1600HV 5mm Tungsten carbide |

5000HV 3mm synthetic diamond |

|

|

Impact device Diameter Impact device Length Impact device Weight |

20mm

86(147)/ 75mm

50g |

20mm

162mm

80g |

20mm

141mm

75g |

30mm

254mm

250g |

20mm

155mm

80g |

|

|

Max. hardness of workpiece |

940HV |

940HV |

1000HV |

650HB |

1200HV |

|

|

Mean roughness of workpiece surface of the Ra |

1.6μm |

1.6μm |

0.4μm |

6.3μm |

1.6μm |

|

|

Min. weight of sample Measure directly Need support firmly Need coupling tightly |

>5kg 2~5kg 0.05~2kg |

>5kg 2~5kg 0.05~2kg |

>1.5kg 0.5~1.5kg 0.02~0.5kg |

>15kg 5~15kg 0.5~5kg |

>5kg 2~5kg 0.05~2kg |

|

|

Min. thickness of sample coupling tightly Min.layer thickness for surface harden |

5mm

≥0.8mm |

5mm

≥0.8mm |

1mm

≥0.2mm |

10mm

≥1.2mm |

5mm

≥0.8mm |

|

|

Size of tip indentation |

||||||

|

Hardness 300HV |

Indentation diameter |

0.54mm |

0.54mm |

0.38mm |

1.03mm |

0.54mm |

|

Indentation depth |

24μm |

24μm |

12μm |

53μm |

24μm |

|

|

Hardness 600HV |

Indentation diameter |

0.54mm |

0.54mm |

0.32mm |

0.90mm |

0.54mm |

|

Indentation depth |

17μm |

17μm |

8μm |

41μm |

17μm |

|

|

Hardness 800HV |

Indentation diameter |

0.35mm |

0.35mm |

0.35mm |

– |

0.35mm |

|

Indentation depth |

10μm |

10μm |

7μm |

– |

10μm |

|

|

Available type of impact device |

D: General test

DC: Hole or hollow-cylindrical test

DL: Slender narrow groove or hole test

|

D+15: groove or reentrant surface |

C: small, light, thin parts or surface of hardend layer |

G: large, thick, heavy or rough surface steel |

E: super high hardness material |

|

|

Type of Impact Device |

Distance of center of the two indentations |

Distance of center of the indentation to sample edge |

|

Not less than (mm) |

Not less than (mm) |

|

|

D、DC |

3 |

5 |

|

DL |

3 |

5 |

|

D+15 |

3 |

5 |

|

G |

4 |

8 |

|

E |

3 |

5 |

|

C |

2 |

4 |

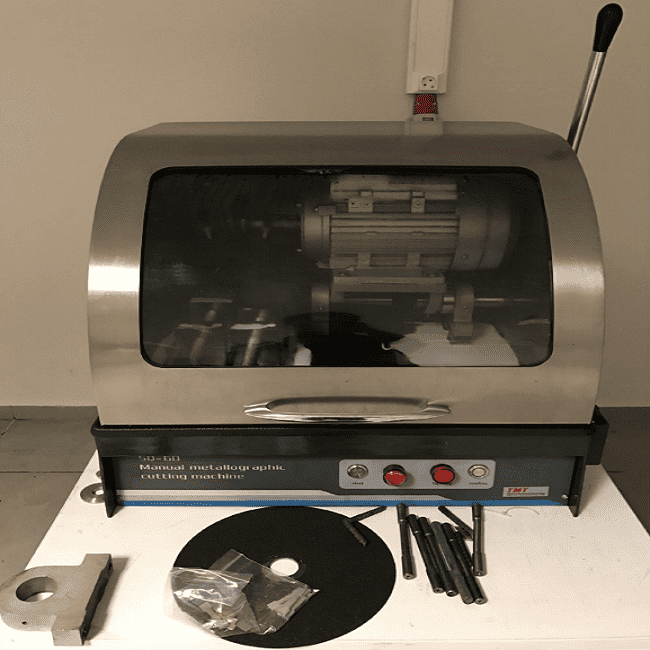

Product detail pictures:

Related Product Guide:

We have now probably the most innovative production equipment, experienced and qualified engineers and workers, regarded high quality control systems and also a friendly expert income team pre/after-sales support for Chinese Professional Hardness Machine - The Impact Device of Hardness Tester – TMTeck , The product will supply to all over the world, such as: Algeria, Mexico, Iraq, Our expert engineering team will generally be prepared to serve you for consultation and feedback. We're able to also give you with free of charge samples to meet your requirements. Best efforts will likely be produced to provide you the best service and merchandise. When you are keen on our business and items, make sure you speak to us by sending us emails or call us quickly. In an effort to know our merchandise and company extra, you may come to our factory to view it. We'll generally welcome guests from all over the world to our business to create business relations with us. Be sure to feel cost-free to speak to us for small business and we believe we are going to share the best trading experience with all our merchants.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.