China OEM Rockwell Superficial Hardness - WEBSTER HARDNESS TESTER – TMTeck

China OEM Rockwell Superficial Hardness - WEBSTER HARDNESS TESTER – TMTeck Detail:

W Series Webster Tester is a portable instrument which can on-site test soft metals quickly. The Webster Hardness Tester is used to inspect the result of heat treatment, to sort the materials in the warehouse, and to test the long workpieces inconvenient taken to the lab. The Webster hardness tester is very suitable for quality inspection of batch products one by one in the production field. The hardness value can be read directly on the indicator dial.

MODEL B

Webster Hardness Tester is the choice of virtually every aluminum extrusion manufacturer in China. This first hardness tester specially crafted for aluminum has improved the aluminum industry.

A test can be completed by one press.

Model W-20 equivalent to Model B Tester

Models for testing brass, copper and mild steel respectively

Modification models for testing thick pieces or slim tubings

Tests sheets, extrusions, pipes

Very fast, very simple and very portable

Small indentation

Conforms to ASTM B647

Recommended in YS/T420.

Webster Hardness Tester for Aluminum Alloys W-20, W-20a, W-20a, W-20b

|

MODEL |

Dimension of specimen |

NET WEIGHT |

APPLICATIONS |

|

W-20 |

0.8- 6mm |

0.5KG |

regular type for aluminum alloy profile, pipe and sheet |

|

W-20a |

0.8–13mm |

0.5KG |

thick wall aluminum alloy material |

|

W-20b |

Min Dia: 6mm |

0.5KG |

aluminum alloy pipe of small diameter and aluminum alloy |

Webster Hardness Tester for Copper Alloys W-B75, W-B75b, W-BB75, W-BB75b

|

MODEL |

Dimension of specimen |

NET WEIGHT |

APPLICATIONS |

|

W-B75 |

Thickness: 0.8 – 6mm |

0.5KG |

extra-hard aluminum, brass |

|

W-B75b |

Min Dia: 6mm |

0.5KG |

slim extra-hard aluminum or brass pipe |

|

W-BB75 |

Thickness: 0.8–6mm |

0.5KG |

copper and soft copper alloys such as annealed brass |

|

W-BB75b |

Min Dia: 6mm |

0.5KG |

copper or annealed brass pipe |

Webster Hardness Tester for Mild Steel W-B92

|

MODEL |

Thickness of specimen |

NET WEIGHT |

APPLICATIONS |

|

W-B92 |

0.8 – 6mm |

0.5KG |

soft steel materials not exceeding 230 HV, such as cold rolled sheet, hot rolled sheet and galvanized sheet etc. |

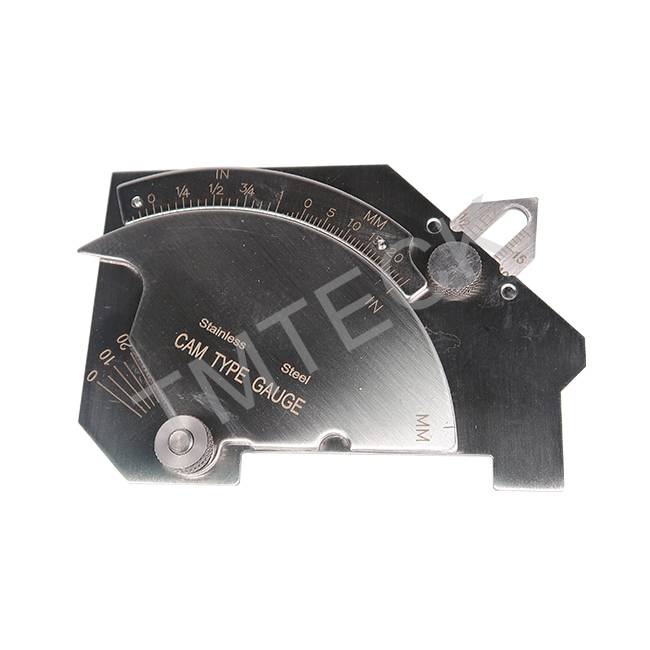

Product detail pictures:

Related Product Guide:

Our personnel are always inside the spirit of "continuous improvement and excellence", and together with the outstanding excellent goods, favorable price and good after-sales services, we try to gain every customer's trust for China OEM Rockwell Superficial Hardness - WEBSTER HARDNESS TESTER – TMTeck , The product will supply to all over the world, such as: Rotterdam, Jamaica, Indonesia, Ensuring high product quality by choosing the best suppliers, we have also implemented comprehensive quality control processes throughout our sourcing procedures. Meanwhile, our access to a large range of factories, coupled with our excellent management, also ensures that we can quickly fill your requirements at the best prices, regardless the order size.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.