2021 China New Design Ultrasonic Flaw Detector Working - TMTECK TC-200 Crack detector for Detecting cracks under thick coatings – TMTeck

2021 China New Design Ultrasonic Flaw Detector Working - TMTECK TC-200 Crack detector for Detecting cracks under thick coatings – TMTeck Detail:

TMTECK TC-200 Crack detector

Crack detection has never been easier or more affordable!

Detects and measures surface cracks in steel – even under thick protective coatings!

Inspect:

Bridges and buildings and other structures

Amusement park rides

Mining and earth moving equipment

Cranes and other lifting equipment

Ships, tanks, military hardware

Pipelines, pressure vessels and oil field equipment

Signal Light Masts, etc.

Features:

Detects cracks under thick coatings

Simple to use

Indicates crack severity (depth)

Accurately find the crack tip

Minimal training required

No need to remove paint and other coatings.

No need to remove oil and grease

Economical

Fast – scan a foot of weld in 10 seconds!

Minimize the use of dye penetrant and magnetic particle inspection (use only to prove-up test results).

Less expensive than eddy current and ACFM instruments

Light weight – 0.6 lb. (300gr.)

No consumables

No mess

14 hour battery operation

Water resistant case (IP-65)

SET-UP:

Place a plastic shim of similar thickness to your coating on the test block. Place the probe over a defect free area and press the “balance” button

Rotate probe so that finger grip is parallel to the notch

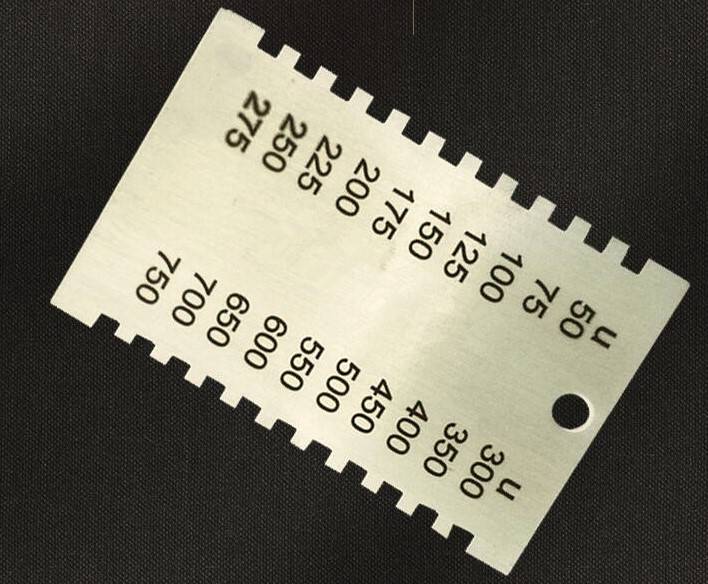

Scan the probe over the appropriate notch in the test block and adjust the sensitivity buttons as required to achieve the required sensitivity.

OPERATION:

plate and pipe:

Scan the area of interest in a Zigzag pattern, repeat at 90 degrees.

welds:

HAZ

Place the probe over the Heat Affected Zone immediately adjacent to the weld and scan the length of the weld. Move the probe 1/8” (3mm) and scan the length of the weld, repeat this process until ½” (12.5mm) is covered on either side of the weld. Note: the probe finger grip should be parallel with the weld.

WELD CROWN

Scan the weld crown in a Zigzag pattern. On bare, rough welds, it is helpful to place a plastic sheet or tape over the weld.

THEORY OF OPERATION:

The probe contains a transmitter and receiver. The transmitter creates a stable AC

magnetic field in the test material that is disrupted by a crack. The receiver in the

probe is a proprietary semi-conductor magneto-sensitive device that detects and

measures the resultant magnetic flux leakage that indicates the presence and severity of a crack.

Product detail pictures:

Related Product Guide:

Responsible excellent and fantastic credit rating standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, buyer supreme" for 2021 China New Design Ultrasonic Flaw Detector Working - TMTECK TC-200 Crack detector for Detecting cracks under thick coatings – TMTeck , The product will supply to all over the world, such as: Bulgaria, Birmingham, Libya, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part products. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!